In the industrial drying, particularly in the chemical, pharmaceutical, and nutraceutical sectors, numerous technologies are designed to ensure a controlled drying process, minimizing the risk of chemical-physical alterations in the treated products. Vacuum drying systems, static dryers with heated plates, and dryers for heat-sensitive products represent advanced solutions for the large-scale removal of solvents from wet powders.

To navigate the various available technologies, it is useful to understand three of the main solutions for chemical and pharmaceutical drying that do not involve moving parts: fluid bed drying, hot air dryers, and vacuum drying. Each of these technologies offers specific advantages depending on the type of product being processed and the objectives of the production process.

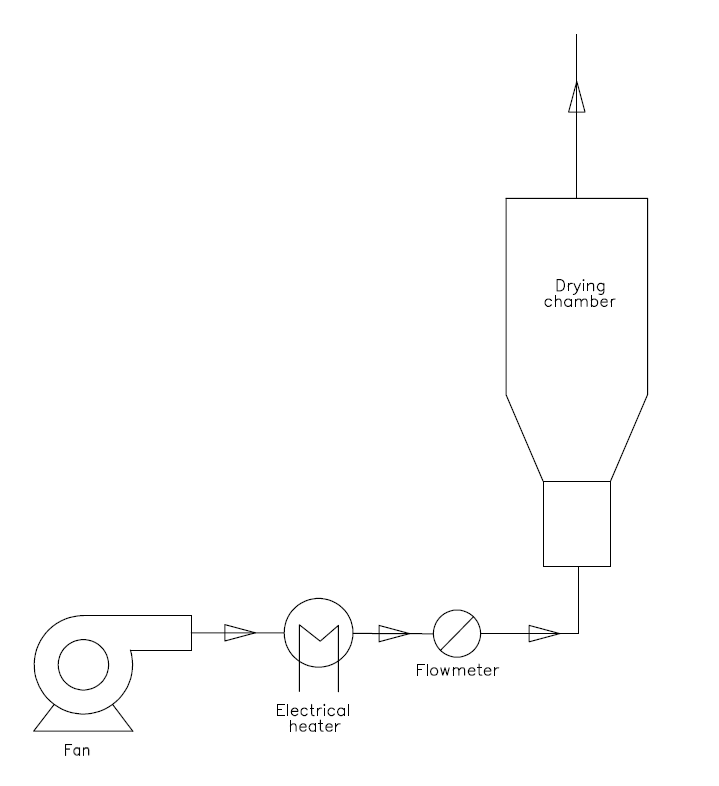

Fluid bed dryers: operation and applications in the pharma field

Fluid bed dryers operate based on the principle of fluidization, by which granular or powdered products can be processed. In this process, a stream of thermally controlled gas is pushed evenly, from the bottom upward, through a bed of solid particles in such a way as to cause them to separate and vibrate, until, if the process requires so, to swirl turbulently within the dryer for high fluid velocities. As it mixes with the hot fluid, moisture is gradually removed from the product as it increases its temperature, resulting in possible chemical, physical and biological changes, depending on the thermal sensitivity of the product being treated.

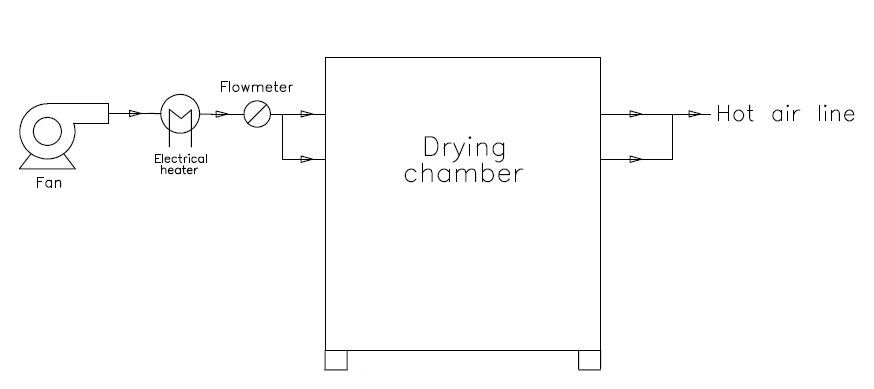

Hot air dryers: efficiency and uses in industry and pharmaceuticals

Hot air dryers, or hot air ovens, use convection of air at high temperatures to lap the product and transmit heat through convection. The movement of the heating fluid is guided, is decided at the design stage, and depends on the process to be carried out, as well as the layout of the product. This technology is used in drying treatments of wet and nonheat-sensitive products, as well as for sterilization, but it finds better use in industrial applications for heat treatments of metals, such as stress relief, stabilization, and aging.

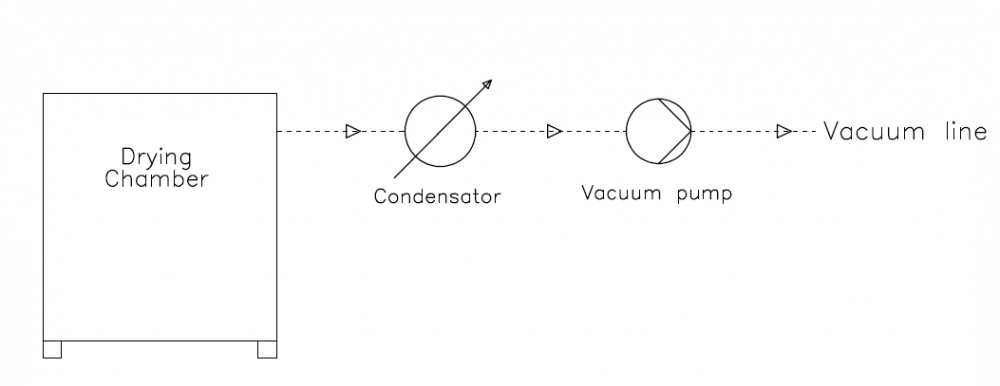

Vacuum drying: the ideal solution for thermo-sensitive products

Static vacuum dryers manage to take advantage of the benefits associated with low pressure and controlled temperature. The product is placed on shelves, usually inside trays, and then subjected to a high vacuum while heat is supplied by conduction.

To date, this system proves to be the best regarding the treatment of temperature-sensitive products and live products since, thanks to the low pressure, it is possible to remove moisture from the product at lower temperatures than those needed at ambient pressure, avoiding heating of the product that could compromise its properties. Drying is progressive and controlled.

Multispray® Italvacuum: innovation in static drying with absolute vacuum.

Italvacuum has been operating in the pharmaceutical, nutraceutical and fine chemical world for 85 years, thanks to the production of vacuum pumps and drying equipment, able to provide customers with turnkey solutions, as well as all the necessary assistance in the pre - and post - sales phase. As experience has grown, we have focused our energies on the development and refinement of various drying equipment, both static and dynamic, including the Multispray® cabinet dryer.

This static cabinet dryer, available in fixed-plate and removable-plate versions, in multiple sizes, is designed to work in absolute vacuum, while heat supply is provided by the plates, the ribs that wrap around the structure, and the door, where different heating fluids can be circulated, depending on the customer's needs.

Thanks to the patented Multispray® system, consisting of a C.I.P. diffuser and a mobile washing unit, rapid, effective, repeatable and certifiable cleaning is also possible. In this way, the chamber and internal shelves are cleaned in minutes, saving significant time and minimizing liquid consumption.

If you would like to learn more, visit the Multispray® page or contact us at marketing@italvacuum.com

__________________________________

Discover all our vacuum dryers for the pharmaceutical industry

ENG

ENG ITA

ITA FRA

FRA ESP

ESP DEU

DEU