Italvacuum ‘s solution to gently optimise vacuum drying process of pharmaceutical powders

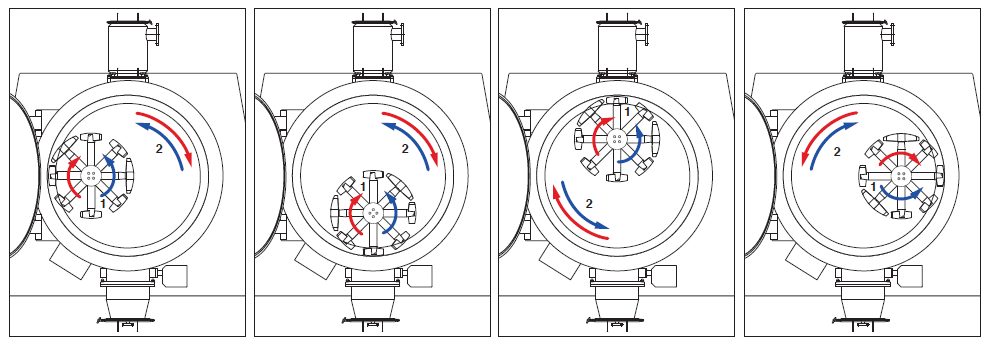

The Italvacuum Planex® System horizontal multi-patented vacuum dryer features a "two independent movements" Heated Agitator Shaft

able to rotate both on its own axis and tangentially to the drying chamber.

The combined dual rotation of the agitator and its reduced dimensions with respect to the drying chamber allow for excellent mass handling, and a significant reduction in drying time due to the increased surface area of product exposed to evaporation.

Thanks to the eccentric position of the agitator, which guarantees different movements, managed by a single software through specific automatic programmes, Planex® System has a wide flexibility in the quantity of product that can be loaded.

This feature allows customised work cycles, including the 'Stop & Swing', designed to handle even small batches.

In addition, the special profile and small size of the agitator leads to a significant reduction in the energy dissipated in the form of friction and a consequently low heat transfer to the product. In addition, they ensure that processes are run with lower energy consumption than conventional horizontal dryers, whose concentric agitator has a single duty cycle.

Mechanical and thermal stresses on the product are also lower than with conventional horizontal dryers with concentric agitator. Thanks to the double ZeroFriction® movement of the agitator, made possible by the special profile of the blades, the heating effect due to the product rubbing against the surface of the drying chamber is prevented, making the Planex® System ideal for processing the most delicate thermolabile products such as active pharmaceutical ingredients and fine chemical powders.

Finally, the minimal gap between the blades and the surface of the drying chamber prevents the formation of agglomerates, ensuring the product a fine particle size at the end of the process and a minimal hold-up.

ENG

ENG ITA

ITA FRA

FRA ESP

ESP DEU

DEU