The tightening of regulatory requirements by national and international public authorities operating in the pharmaceutical and medical sector (in Italy AIFA - Agenzia Italiana del Farmaco - and in Germany BfArM - Federal Institute for Drugs and Medical Devices), combined with the growing complexity of pharmaceutical substances and their synthesis processes, compels equipment manufacturers to adopt increasingly sophisticated technologies to ensure compliance and production quality.

In this evolving context, the selection of metallic materials, depending on whether or not they are in contact with the substance being processed, represents one of the critical factors in the pharmaceutical and fine chemical industry. The chemical compatibility of surfaces directly determines the quality of the final product and compliance with required market specifications.

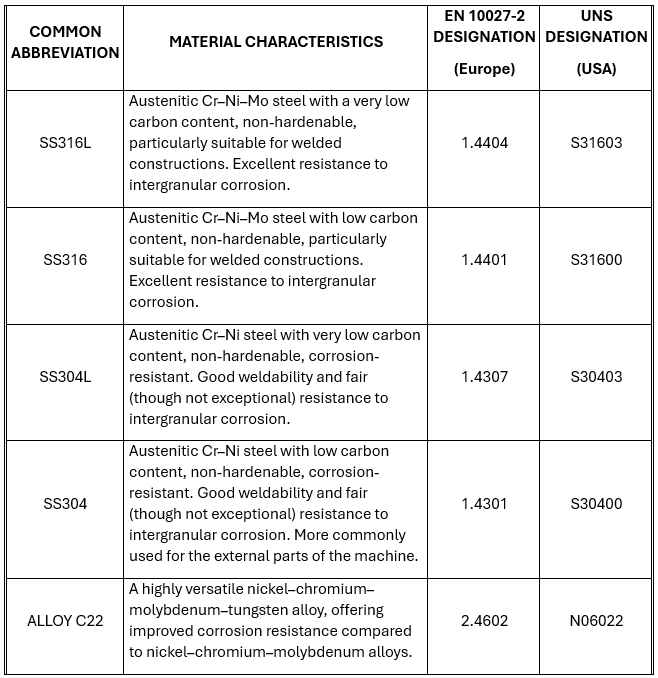

Classification of stainless steels and alloys used in the Pharmaceutical Industry

The metallic materials in contact with the process vary according to the type and chemical-physical characteristics of the product being processed, first and foremost, its corrosiveness and abrasiveness. A pragmatic example is drying, a process in which a liquid solution or a moist powder changes its physical characteristics because of the evaporation of a solvent, often corrosive.

The main construction materials used by Italvacuum in the manufacture of vacuum dryers for the pharmaceutical industry.

Alloy C22 metal alloy vs glass lining (glass-lined steel)

As shown in Table 1, the most suitable construction materials for resisting the most aggressive corrosion processes are nickel-chromium-molybdenum-tungsten alloys (Alloy C22). Steels such as AISI 304 and AISI 304L, in the pharmaceutical sector, are instead used for components or plant sections not directly in contact with the treated product.

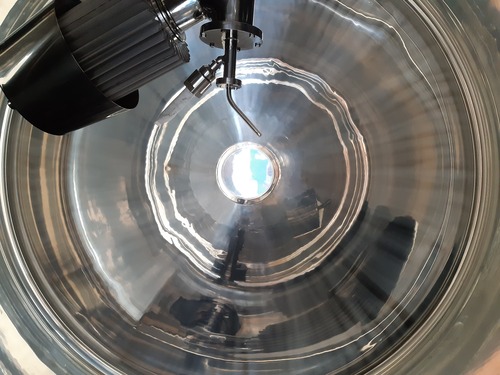

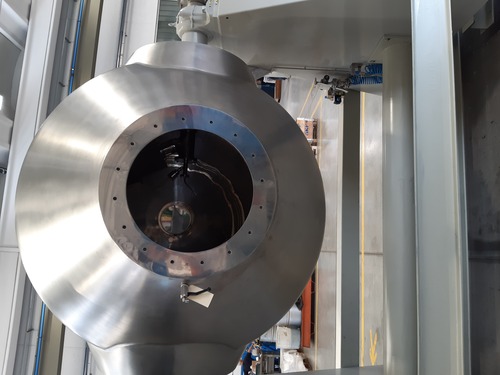

Images of the BiEvolution system RB3000 (3000 Litres) by Italvacuum: - Material of internal components in contact with the product: Alloy C22

- Material of external cleanroom components: AISI 304L

For critical applications characterized by the high corrosive power of the product or solvent, industry gravitates toward two consolidated construction solutions:

1. Alloy C22 – High corrosion-resistant metal alloy

2. Glass lining – Carbon steel with vitreous enamel coating

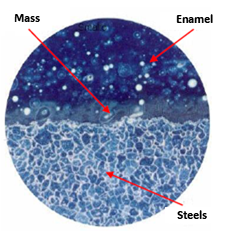

Glass-lined steel is a composite material consisting of an enamel layer firmly bonded to the metal substrate through an initial “ground coat,” whose sole function is to improve adhesion between steel and the overlying enamel.

The enamel, with a thickness between 1 and 2 mm, is applied to the internal wall and subsequently fired in dedicated furnaces up to about 900°C.

Images showing a glass-lined apparatus and the typical steel–enamel interface structure.

However, compared with equipment constructed in Alloy C22 or stainless steel, the thickness of material used for equipment intended for ceramic enamel lining is significantly greater.

This structural difference derives from constraints imposed by the glass lining process: the high firing temperatures (≈900°C) required for enamel vitrification make the use of carbon steel mandatory as the substrate. Other materials, such as special alloys, would undergo structural deformation and metallurgical alterations during high-temperature treatment, compromising coating integrity.

Carbon steel, while ensuring dimensional stability during firing without undesired reactions, exhibits lower mechanical characteristics than advanced alloys used in Alloy C22 systems. To compensate, construction thicknesses must be increased to maintain mechanical strength and safety parameters. This oversizing increases total mass, impacting support structure sizing, installation and handling costs, and overall plant footprint.

Construction advantages

Alloy C22 equipment, not requiring extreme thermal treatments during fabrication, allows for both reduced wall thicknesses and lower overall manufacturing costs. The reduction in material thickness shortens welding times and improves the efficiency of internal handling, with a positive impact on production costs. In the chemical-pharmaceutical industry, carbon steel is used exclusively as a structural and support material, as it inherently lacks adequate corrosion and oxidation resistance for direct contact with the process. Any accidental contact with process substances could lead to product contamination and accelerated material degradation, compromising plant integrity and GMP compliance.

Alloy C22, therefore, represents an advanced construction solution. In such equipment, carbon steel is used only for secondary elements that do not come into direct contact with the process, or is completely replaced by stainless steels (AISI 304 or AISI 316), depending on design choices and client specifications. This clearly distinguishes Alloy C22 from glass-lined equipment, where the use of carbon steel as a structural substrate is essential to provide mechanical strength and stability during thermal cycles, making the system more vulnerable to potential damage of the protective coating.

Thermal efficiency and heat transfer

Another key aspect in chemical and pharmaceutical processes lies in the heating and cooling operations of the processed product. These phases require efficiency in heat transfer and uniform temperature across all contact surfaces.

In Alloy C22 equipment, thermal transmission occurs directly between the metal surface and the process substance, ensuring speed and efficiency (thermal conductivity coefficient λC22 approximately 9.6 W·m⁻¹·K⁻¹).

In contrast, in glass-lined dryers, heat transfer is mediated by the presence of a ceramic layer between the metal and the product, resulting in higher overall thermal resistance and, consequently, increased energy requirements during temperature control phases (thermal conductivity λ of enamelled steel approximately 1.2 W·m⁻¹·K⁻¹). This also translates into higher CO₂ emissions, inevitably associated with the usual energy production processes.

Vacuum drying processes, for example, require extreme thermal cycles characterized by rapid heating and cooling, generating severe temperature gradients within the equipment. These operational cycles typically involve multi-step heating ramps to optimize solvent evaporation, followed by accelerated cooling phases necessary to stabilize the product and allow safe handling.

During these thermal shocks, the different rates of expansion and contraction of the materials subject the surfaces to significant mechanical stresses. Equipment made entirely of Alloy C22 or high-strength stainless steels shows excellent tolerance to these thermal stresses thanks to its structural homogeneity and the metal alloy’s thermo-mechanical properties, which ensure uniform stress distribution without points of fragility.

Enamelled surfaces, on the other hand, exhibit an intrinsic vulnerability due to the different nature of the constituent materials: the differing thermal expansion coefficients between the metal substrate and the ceramic coating generate interfacial stresses that can cause microcracks in the glass or localized delaminations. Even if initially microscopic, such damage progressively compromises the integrity of the protective barrier, exposing the underlying carbon steel to direct chemical attack from the process.

Workability and customization: versatility vs structural limits

In addition to the advantages outlined so far, another key strength of dryers made from Alloy C22 lies in their high workability and design versatility. The good malleability of this alloy allows the installation of numerous accessories—such as measurement instruments, sight glasses, and sampling nozzles—directly in contact with the product, meeting the customization requirements typical of the pharmaceutical industry. These modifications can be implemented through welding operations (MIG, MAG, or GTAW) followed by surface treatments (electropolishing, passivation, pickling), ensuring continuity and uniformity of the contact surfaces while complying with cleanliness and asepsis requirements.

In contrast, in glass-lined equipment, adding openings or accessories faces a technical limitation due to the nature of the coating itself: to avoid discontinuities or weakening of the enamel, the area near the nozzles is coated only up to a few millimeters from the edge and completed with a second enamel layer of a different color. Although this solution is well-established, it constitutes a potential weak point in terms of chemical and mechanical resistance compared to the intrinsic homogeneity guaranteed by metal alloys.

Mechanical resistance and maintenance

Another fundamental aspect in the comparison between Alloy C22 and glass-lined surfaces concerns extraordinary maintenance and mechanical resistance to accidental impacts. Localized impacts or mechanical stresses on equipment made of Alloy C22 do not compromise the structural integrity or functionality of the dryer, thanks to the high toughness and impact resistance inherent to this alloy.

In contrast, glass-lined surfaces, due to their fragile ceramic nature, are susceptible to chipping or cracking even under moderate impacts, with potential repercussions on process safety and risks of product contamination. Such damage may lead to temporary or permanent decommissioning of the equipment.

Complementing these considerations, extraordinary maintenance of Alloy C22 equipment is fast and economically advantageous. Thanks to the malleability and workability of the alloy, restorations can be performed through localized mechanical interventions, such as polishing, grinding, or welding repairs, followed by passivation, without compromising the overall integrity of the system.

Conversely, repairing damaged glass-lined surfaces requires more complex and invasive procedures, generally involving drilling the compromised area, inserting reinforcements or PTFE inserts to seal the zone, and, in some cases, complete replacement of the component if the damage is extensive.

Cleaning and GMP compliance

Another key aspect in pharmaceutical processes is surface cleanliness.

Equipment made from Alloy C22, thanks to its homogeneous metal surface, offers maximum cleanability, minimizing product residue adhesion and facilitating cleaning-in-place (CIP) or sterilization-in-place (SIP) operations.

In contrast, glass-lined surfaces, while providing good chemical inertness, exhibit discontinuities around nozzles and a certain microporosity in the ceramic coating, which can promote the accumulation of contaminants or the retention of residues in case of microcracks or chipping.

ATEX safety and electrical conductivity

From an ATEX perspective, Alloy C22, being a conductive metal material, ensures complete electrical continuity of internal surfaces, preventing the accumulation of electrostatic charges and fully complying with safety requirements for potentially explosive atmospheres.

In contrast, the enamel coating, due to its dielectric nature, interrupts the continuity between the product and the underlying metal structure, requiring specific design measures, such as grounding conductors or conductive metal inserts, to ensure adequate electrostatic dissipation in accordance with regulations.

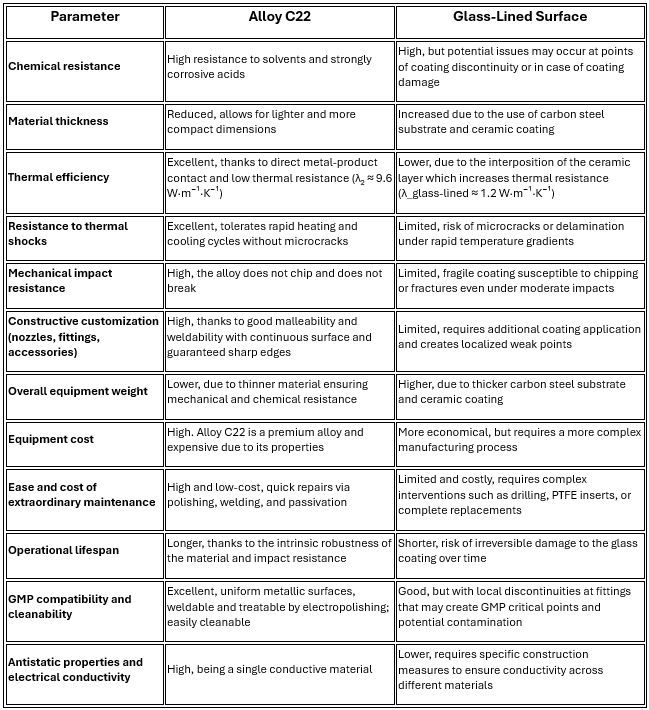

The main characteristics of the two construction solutions under consideration are summarized below.

Table 2

Comparison of the main characteristics of the two construction solutions: Alloy C22 and carbon steel with an enamelled surface.

Economic analysis and total cost of ownership

The choice of material, therefore, is a determining factor in ensuring safety, durability, operational efficiency, and compliance with GMP requirements in chemical-pharmaceutical processes.

Although the initial purchase cost of equipment made from Alloy C22 is generally higher than that of items constructed from enamelled carbon steel, a comprehensive evaluation based on the Total Cost of Ownership (TCO) shows that this investment results in long-term economic savings.

This is mainly due to the longer operational life, reduced need for extraordinary maintenance, better thermal efficiency, and the complete absence of issues related to chipping, microcracking, or delamination typical of glass surfaces.

Conclusions: Italvacuum’s construction choices

Italvacuum dryers are engineered for stringent process demands. Mirror-polished internal surfaces (Ra < 0.4 μm) minimize buildup and ensure vacuum tightness. Beyond standard austenitic stainless construction, Alloy C22 is employed for severe applications.

Its intrinsic properties—chemical and mechanical resistance, thermal shock tolerance, versatility, and workability—make it the most robust, reliable, and hygienically safe solution.

Alloy C22 thus stands as a state-of-the-art choice for drying and reaction equipment in corrosive, thermally stressed environments, ensuring operational continuity and GMP compliance, and confirming leadership among advanced metallic materials for the pharmaceutical and fine chemical sector.

ENG

ENG ITA

ITA FRA

FRA ESP

ESP DEU

DEU