Industrial

Vacuum Pump

issues?

Industrial

Vacuum Pump

issues?

This has always been a problem in production processes with the use of dry pumps and dry screw pumps. The presence of solid particles can lead to pump damage and the consequent shut down of the normal process operation.

The creation of black sludge, a carbon by-product, with a high tendency to solidify, especially in cold spots, the consequent shut down of the normal process operation.

Liquid transfer into vacuum system and relative blocakge and breakdown of the unit and relative process. Very frequent in fine chemical and pharmaceutical industry.

RESULTS

process downtime

OUR SOLUTION?

First and Last Name

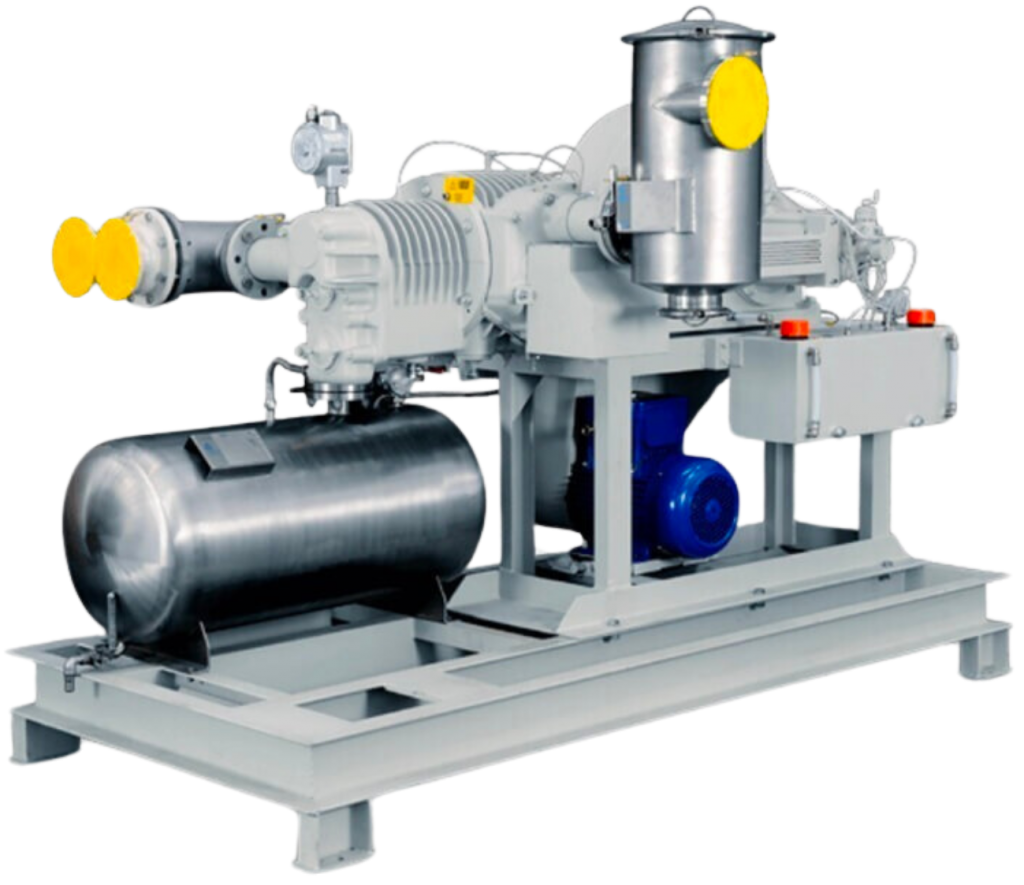

SAURUS 939

Manufacturer

ITALVACUUM

Type

VACUUM PISTON PUMP

Origin

TURIN, ITALY

Duty

solvent extraction – high vacuum

Experience

Pharmaceutical, fine chemical

and chemical companies

Notable Features

RANGE OF FLOWRATE

from 81 m3/h up to 3800 m3/h

VACUUM LEVEL

0.03 mbar – 0.022 Thor

Important Characteristics

Gentle and quiet – 250 rpm

noise level <70 dB(A)

Hard worker 24h and 7/7

![]()

More than 1000 in India

Our Customers

OUR KEY TO SUCCESS?

SERVICE

Vacuum Drying technology India

Sole agent in India for Italvacuum since 1995

WHO WE ARE

Italvacuum is one of the world’s leading manufacturers of vacuum pumps and vacuum dryers.

Cutting-edge equipment and systems, customised based on the application and customer’s production requirements. The highest quality levels with total respect for the environment and in compliance with the newest international standards. This has been our mission for more than 80 years. Italvacuum specific services support you in the phase of choice, installation and commissioning of the most appropriate technologies.

PILOT TESTS

Semi-industrial and laboratory drying tests of your products

ENGINEERING

Designers and technicians for you

CUSTOMER SERVICE

Fast and efficient answers for every question

Want to know more?

REQUEST FOR INFORMATION

© Copyright 2024 – Italvacuum S.r.l. – C.F/P.Iva 04917380018 – REA O-670462 – Cap.Soc. € 100.000 i.v.