Bi-evolution Dryer is able to carry out the complete extraction of solvents and water from wet masses, usually after centrifugation and filtration steps.

Bi-Evolution Dryer® is multi-product. It has been designed for the widest range of possible products with crystalline or amorphous structure, whether they are intermediates or fine chemicals. It is also efficient at drying products that are friable, easily degraded, thermosensitive and photosensitive, as well as sterile active pharmaceutical ingredients or chemically reactive ingredients.

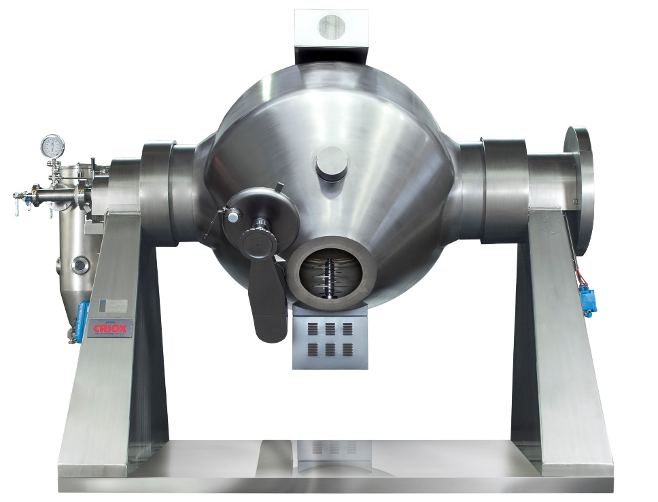

Double cone rotary vacuum dryer

Maximum cleanability

• meet the validation procedures set by FDA Standards;

• avoid product contamination;

• help and speed up changes in product campaigns.

Inspection and dismantling of internal parts

By opening the manhole port lid and the loading hopper. That allows to perform the SWAB test required by the FDA standards for the validation of the washing procedures, with extreme ease and safety.

Clean room installation

Bi-Evolution Dryer® can be easily cleaned both inside and outside. Due to the waterproof casing of the entire machine (cGMP “particle free” configuration), covering insulation, electrical and hydraulic circuits, the external cleaning is extremely easy and effective.

Effective filtering systems

The filtering unit must be able to keep all of the powder in the drying chamber, letting only the solvent vapours pass through.

Dimensions

Bi-Evolution Dryer® can be designed for a wide range of capacities with total volumes ranging from 55 up to 12,000 litres (from 14 up to 3.170 gallons) per batch in. The maximum recommended loading level is a function of the individual product.

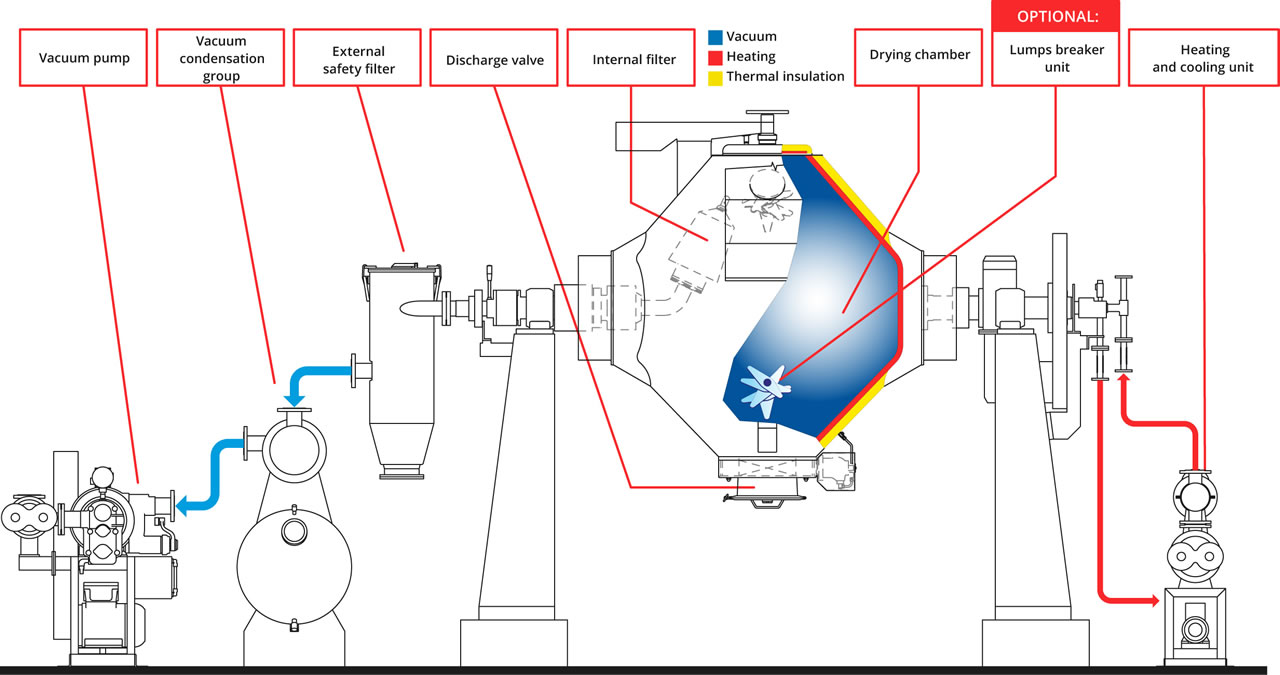

Turn-key systems

Italvacuum is the only manufacturer in the world that, in addition to the dryer itself, can design and build internally all the auxiliary units to complete the system, properly sizing them to meet every process requirement, vacuum system included:

Any agglomeration phenomena?

Our solution: Lump Breakers Units

Two set of lump-breakers blades can be installed in the double-cone drying chamber.

They not only prevent the agglomerate formation in the dried batch, but also allow to powderize it over the last phase of the process.

Furthermore, they reduce considerably the drying time and ensure extremely low final moisture values.

With the use of this optional the machine falls under the international Criox® System patent: the rotary vacuum dryer / powderer designed and manufactured by Italvacuum.

Inox version – complete installation in clean Room with lump breakers

A shape designed for the best possible results

Effective filtering systems on the inner suction pipe

Maximum cleanability

Internal washing

Inspection and dismantling of internal parts

Clean room installation

BI-EVOLUTION DRYER INSTALLATIONS

COMPANY

Leader global science and technology company

PRODUCTION

High-Performance thermoplastics

SYSTEM

Bi evolution RB.3000 – Double Cone Rotary Vacuum Dryer

DESCRIPTION

Turn key solution: in addition to the vacuum dryer we can provide to the customers all the components that complete the system, including the vacuum pump, sized to meet any process requirement. In this case the system is complete with Process filter and any external safety filter, vacuum condensation unit with tank for recovering the extracted solvents, heating and cooling unit for temperature control and accessories, Loading and unloading systems for powders and control panels with PLC

The system is used to remove the very last traces of solvent into the treated product with the application of High Vacuum combined with a proper heating Temperature.

COMPANY

Leading provider of equipment and services solutions for packaging beverage

PRODUCTION

Packaging beverage solutions – SSP (Solid State Polymerization) purpose.

SYSTEM

Bi evolution RB. 55 (55 l Double Cone Rotary Vacuum Dryer)

DESCRIPTION

The system the system is complete with process filter and any external safety filter, vacuum condensation unit with tank for recovering the extracted solvents, heating and cooling unit for temperature control and accessories, Loading and unloading systems for powders and control panels with PLC.

WHO WE ARE

Italvacuum is one of the world’s leading manufacturers of vacuum pumps and vacuum dryers.

Cutting-edge equipment and systems, customised based on the application and customer’s production requirements. The highest quality levels with total respect for the environment and in compliance with the newest international standards. This has been our mission for more than 80 years. Italvacuum specific services support you in the phase of choice, installation and commissioning of the most appropriate technologies.

PILOT TESTS

Semi-industrial and laboratory drying tests of your products

ENGINEERING

Designers and technicians for you

CUSTOMER SERVICE

Fast and efficient answers for every question

For DOUBLE CONE ROTARY VACUUM DRYER or any other informations

please fill the form

Italvacuum S.r.l. – C.F/P.Iva 04917380018 – REA O-670462 – Cap.Soc. € 100.000 i.v. | Privacy Policy | Cookie Policy